Introduction

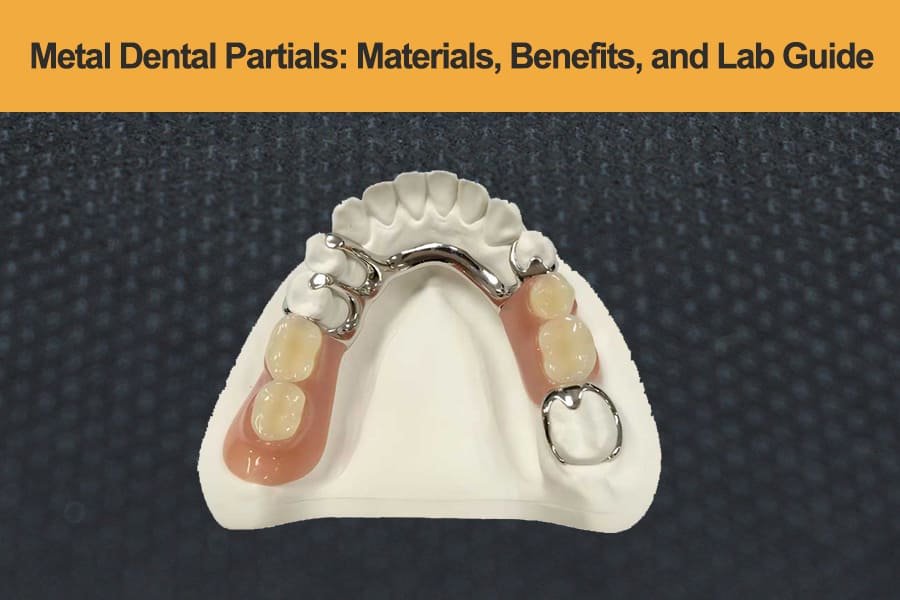

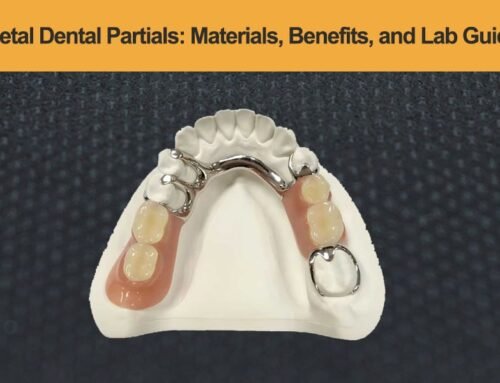

Dental implant parts are the different pieces that come together to replace a missing tooth. These parts include the implant placed in the jawbone, the connector that sits on top of it, and the final crown that looks and functions like a natural tooth. When each part fits correctly, the implant can remain stable and comfortable for many years.

Understanding these components helps dental professionals avoid common problems such as loose screws or poor fit. In this guide, based on practical experience from SF Dental Lab, we explain the main dental implant parts in clear, simple terms and show why quality and precision matter for long-term implant success.

What Are Dental Implant Parts?

Dental implant parts refer to all the individual components that make up a complete dental implant system. Instead of being a single product, a dental implant is a combination of carefully designed parts that work together to replace a missing tooth both functionally and visually.

These parts can generally be divided into two categories. The first includes surgical components, such as the implant fixture that is placed into the jawbone. The second includes prosthetic components, such as the abutment and crown, which sit above the gum line and restore chewing function and appearance.

Each dental implant part has a specific role. If one component is poorly designed or does not fit properly with the others, it can affect the entire restoration. Problems such as instability, screw loosening, or discomfort often come from mismatched or low-quality components rather than the implant concept itself.

For this reason, understanding dental implant parts—and how they fit together as a system—is essential for achieving reliable, long-term results. Proper design, accurate manufacturing, and correct component selection all play a key role in implant success.

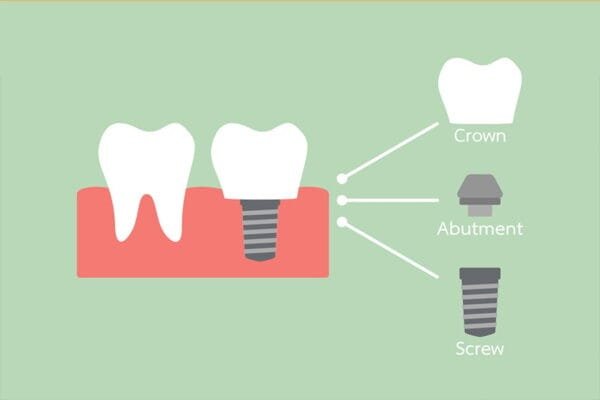

The Three Core Parts of a Dental Implant System

A standard dental implant system is built around three core parts. Each one has a clear function, and all three must work together for the implant to be stable, functional, and long-lasting.

Implant Fixture (Implant Post)

The implant fixture is the part placed directly into the jawbone. It acts as an artificial tooth root and provides the foundation for the entire restoration. Most fixtures are made from titanium or titanium alloy because these materials bond well with bone. A stable, well-integrated fixture is essential for long-term implant success.

Abutment

The abutment connects the implant fixture to the visible tooth restoration. It sits on top of the implant and passes through the gum tissue, creating a secure base for the crown. Abutments can be standard or custom-made, depending on the case. Proper abutment fit is critical, as poor accuracy can lead to gaps, screw loosening, or gum irritation.

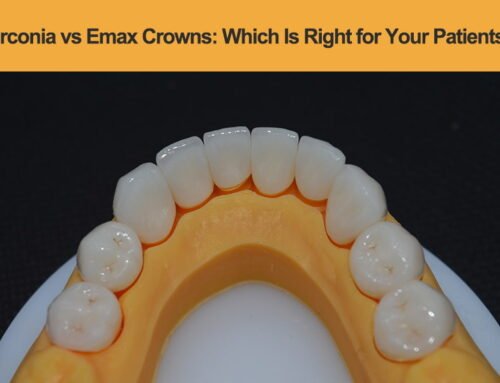

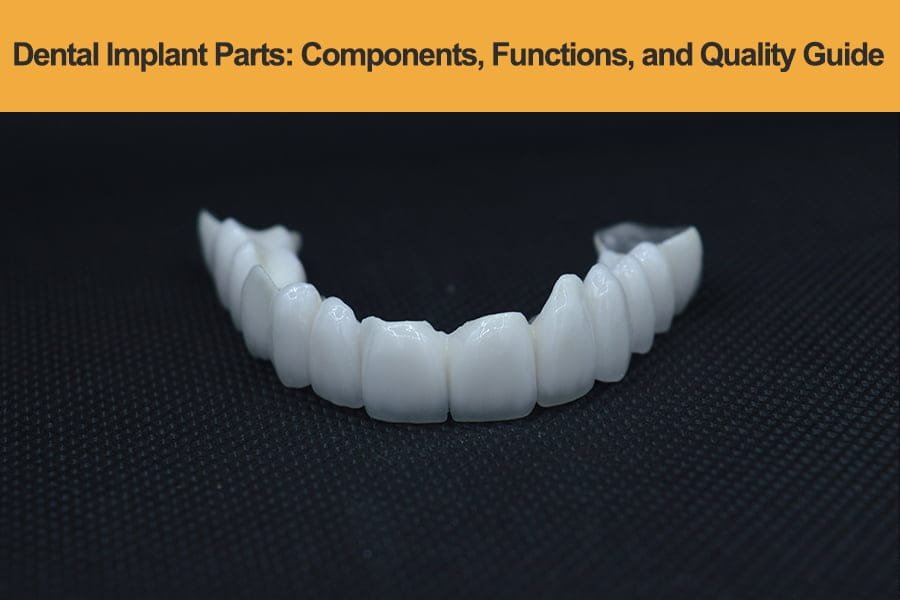

Dental Crown (Final Restoration)

The dental crown is the visible part of the implant and is designed to look and function like a natural tooth. It is fixed onto the abutment and customized to match the patient’s bite and appearance. While the crown is what patients see, its performance depends heavily on the precision of the implant fixture and abutment beneath it.

Together, these three dental implant parts form a complete system. If any one of them is poorly designed or manufactured, it can affect the comfort, durability, and overall success of the implant restoration.

Additional Dental Implant Parts You Should Know

In addition to the three main components, several supporting dental implant parts play important roles at different stages of treatment. Although these parts are smaller and less visible, they are essential for proper healing, stability, and long-term performance.

Abutment Screw

The abutment screw is used to secure the abutment to the implant fixture. It may appear simple, but it requires very high manufacturing accuracy. Proper screw fit and torque help prevent common issues such as loosening or fracture. Poor-quality screws are a frequent cause of mechanical implant complications.

Healing Abutment (Healing Cap)

A healing abutment is a temporary component placed on the implant during the healing phase. Its purpose is to guide the gum tissue to heal in the correct shape around the implant. Healing abutments come in different heights and diameters to match soft tissue conditions and are removed once healing is complete.

Cover Screw

A cover screw is used when the implant is placed below the gum line and allowed to heal without exposure. It protects the internal connection of the implant during the healing period. After healing, the cover screw is removed and replaced with a healing abutment or final abutment.

Although these parts are not part of the final visible restoration, they directly affect healing quality and long-term stability. Using well-made, compatible components at each stage helps reduce complications and supports predictable implant outcomes.

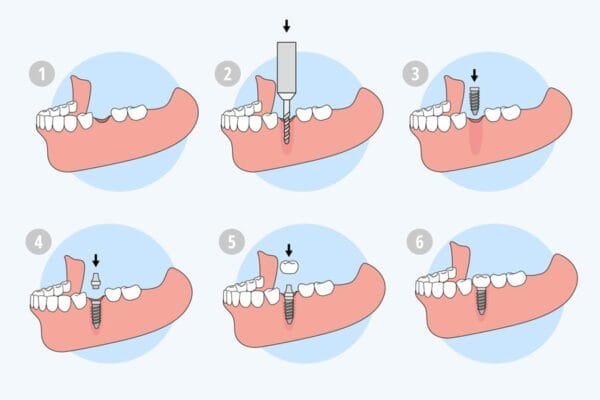

Dental Implant Parts by Treatment Stage

Dental implant parts are not all used at the same time. Instead, different components are placed at different stages of treatment, each serving a specific purpose. Understanding this sequence helps explain why correct part selection is so important.

Surgical Stage

During implant surgery, the implant fixture is placed into the jawbone. In some cases, a cover screw is attached to protect the implant while it heals under the gum tissue. At this stage, accuracy and surface quality of the implant are critical for successful bone integration.

Healing Stage

Once the implant begins to integrate with the bone, a healing abutment may be placed. This component allows the gum tissue to heal properly around the implant and creates a natural-looking emergence profile. The healing stage prepares the site for the final restoration.

Final Restoration Stage

After healing is complete, the healing abutment is removed and replaced with the final abutment, which is secured using an abutment screw. The dental crown is then attached, restoring normal chewing function and appearance. At this stage, precision fit between all parts is essential to ensure comfort, stability, and long-term performance.

Each treatment stage relies on specific dental implant parts working together correctly. Using the right components at the right time helps reduce complications and supports predictable, long-lasting implant results.

Materials Used in Dental Implant Parts

The performance and lifespan of dental implants depend heavily on the materials used in each implant part. High-quality materials improve strength, compatibility with the human body, and long-term reliability.

Titanium

Titanium is the most commonly used material for implant fixtures and many abutments. It is well known for its excellent biocompatibility, meaning the body accepts it easily. Titanium also bonds well with bone, which helps create a strong and stable foundation for the implant. In addition, it offers a good balance of strength and flexibility, reducing the risk of fracture under chewing forces.

Titanium Alloy

Titanium alloys are often used when higher mechanical strength is required, such as for abutments and screws. Compared to pure titanium, alloys provide improved durability while maintaining good biocompatibility. This makes them suitable for cases with higher bite forces or limited space.

Zirconia

Zirconia is mainly used for abutments and crowns, especially in areas where appearance is critical. Its tooth-like color helps prevent dark shadows at the gum line, making it a popular choice for front teeth. Zirconia is strong and highly resistant to wear, although it is typically less flexible than titanium.

Choosing the right material for each dental implant part depends on clinical needs, esthetic requirements, and functional demands. Using appropriate materials helps ensure implant stability, patient comfort, and long-term success.

How Dental Labs Support Implant Restorations

Dental labs play a critical role in the success of implant restorations, especially once the surgical phase is complete. Their responsibility goes beyond making crowns—it includes ensuring that all implant-related parts fit accurately and function together as a system.

One key contribution is the design and fabrication of custom abutments and implant-supported crowns. Using digital impressions and CAD/CAM technology, dental labs can create components that match the patient’s anatomy, bite, and soft tissue conditions. This improves comfort, esthetics, and long-term stability compared to generic solutions.

Dental labs also help manage component compatibility. By working closely with implant system data and clinical instructions, experienced labs ensure that abutments, screws, and restorations match the correct implant connection and tolerances. This reduces the risk of misfit, screw loosening, or mechanical failure.

Quality control is another essential function. Reputable labs inspect materials, verify dimensions, and test fit before delivery. At SF Dental Lab, implant restorations are produced with strict attention to accuracy, communication, and consistency, helping clinics achieve predictable results while controlling cost.

In short, a skilled dental lab acts as a technical partner—supporting implant restorations from design to final delivery and helping ensure reliable, long-term outcomes.

Conclusion

Dental implant restorations rely on accurate, well-matched components to perform reliably in daily use. When implant parts are produced with precision and handled by an experienced team, the entire workflow becomes smoother and more predictable.

SF Dental Lab supports clinics and dental labs outsourcing implant work by providing consistent production, clear communication, and dependable quality for implant-supported crowns and custom abutments.

If you are a clinic or dental lab looking for a reliable outsourcing partner, contact SF Dental Lab to discuss your implant cases and see how we can support your workflow with stable quality and competitive turnaround.