Introduction

Metal dental partials are removable dental appliances that replace one or more missing teeth. They use a metal framework to support artificial teeth, helping patients chew more easily, speak clearly, and maintain a natural-looking smile.

Each metal dental partial is custom-made, so comfort and fit depend on good design and careful lab work. In this guide, we explain metal dental partials in clear, simple terms, including their benefits, limitations, and how they are made. Based on practical experience from SF Dental Lab, this article is written to help clinics and dental labs better understand and manage metal partial cases.

What Are Metal Dental Partials?

Metal dental partials are removable partial dentures designed to replace one or more missing teeth when some natural teeth are still present. They are built on a metal framework that holds artificial teeth in the correct position and anchors the appliance securely to the remaining teeth.

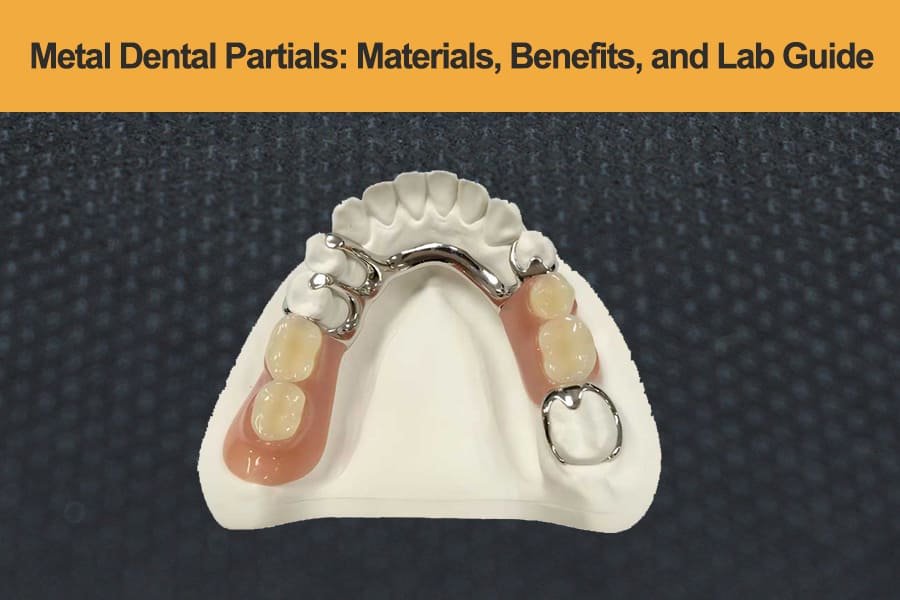

A typical metal dental partial includes three main elements: a metal framework for strength, an acrylic base for support, and artificial teeth made from acrylic or porcelain. The framework is custom-made to fit the patient’s mouth, which helps the partial feel stable and less bulky compared to all-acrylic options.

Because of their strength and precise fit, metal dental partials are commonly chosen when durability, comfort, and long-term use are important. They are easy to remove for cleaning, yet secure enough to function well during daily eating and speaking.

Main Components of Metal Dental Partials

Metal dental partials are made up of several key components that work together to provide strength, stability, and comfort. Each part has a specific function, and accurate design is essential for proper fit.

Metal Framework

The metal framework forms the base of the partial denture. It provides strength while allowing the appliance to remain thin and lightweight. A well-designed framework helps distribute biting forces evenly and improves overall comfort.

Clasps and Rests

Clasps wrap gently around selected natural teeth to hold the partial in place. Rests sit on the chewing surfaces of teeth to support the partial and prevent it from moving toward the gums. Proper clasp and rest design helps improve stability and protect remaining teeth.

Acrylic Base

The acrylic base sits on the gum tissue and supports the artificial teeth. It also helps improve comfort and appearance by blending naturally with the gums.

Artificial Teeth

Replacement teeth are attached to the acrylic base and are typically made from acrylic or porcelain. They are shaped and colored to match the patient’s natural teeth as closely as possible.

When all these components are designed and fabricated correctly, metal dental partials can provide a secure fit, good function, and long-term reliability.

Materials Used in Metal Dental Partials

The performance and comfort of metal dental partials depend largely on the material used for the framework. The two most common options are Chrome Cobalt and Titanium, each with its own advantages.

Chrome Cobalt (Co-Cr)

Chrome Cobalt is the most widely used material for metal dental partials. It is very strong, allowing the framework to be thin while still providing excellent support. This makes the partial lighter and more comfortable for the patient. Co-Cr frameworks are also durable and suitable for long-term use in most clinical cases.

Titanium

Titanium is lighter than Chrome Cobalt and is known for its high biocompatibility. It is often selected for patients who prefer a lighter appliance or have sensitivities to heavier metals. While Titanium offers good strength and comfort, it generally requires more advanced processing and comes at a higher cost.

Choosing the right material depends on the patient’s needs, clinical conditions, and budget. A well-matched material helps ensure comfort, stability, and long-term success of the metal dental partial.

Benefits of Metal Dental Partials

Metal dental partials offer several clear advantages, making them a popular choice for replacing missing teeth:

- Improved chewing ability

The strong metal framework provides good stability, allowing patients to eat more comfortably and efficiently. - Clearer speech

A thinner, well-fitted framework interferes less with tongue movement, helping patients speak more naturally. - Better comfort and fit

Metal partials are lightweight and secure, which reduces movement, sore spots, and irritation during daily use. - Natural-looking appearance

Proper tooth selection and careful design help the partial blend well with natural teeth. - Long service life

Metal frameworks are durable and resist wear, making them a cost-effective solution over time.

These benefits make metal dental partials a reliable option for many partial tooth replacement cases.

Risks and Limitations of Metal Dental Partials

While metal dental partials offer many benefits, there are some limitations that should be considered before treatment:

- Initial discomfort or sore spots

Some patients may experience pressure or irritation when first wearing a metal partial. Minor adjustments are often needed during the early stages. - Possible impact on natural teeth

If the design or fit is not accurate, clasps may place stress on remaining teeth, which can lead to wear or damage over time. - Visibility of metal clasps

In certain cases, metal clasps may be visible when smiling, especially for front teeth. - Material sensitivity or allergies

Metal dental partials are not suitable for patients with allergies to metal or plastic materials. - Not recommended for severe gum disease

Patients with advanced periodontal issues may not be good candidates, as healthy gums and teeth are needed for proper support.

Understanding these risks helps clinics and patients make informed decisions and highlights the importance of proper design and experienced lab support.

How Metal Dental Partials Are Made and Turnaround Time

Case Planning and Impressions

The process begins when SF Dental Lab receives impressions or digital scans along with the prescription. At this stage, tooth position, bite relationship, and support areas are carefully reviewed to ensure the metal dental partial will fit comfortably and function correctly.

Framework Design

Based on the case details, the metal framework is designed to fit closely around the remaining teeth and gums. SF Dental Lab uses both traditional techniques and digital CAD design to achieve accuracy, stability, and patient comfort.

Metal Processing

Once the design is finalized, the framework is produced using the selected material, such as Chrome Cobalt or Titanium. Precision during casting or processing is critical, as even small inaccuracies can affect fit and long-term comfort.

Tooth Setup and Acrylic Processing

After the framework is completed, artificial teeth are positioned, and acrylic is added to support the teeth and contact the gum tissue. This step restores chewing function and natural appearance.

Finishing and Quality Inspection

The final metal dental partial is polished and carefully inspected for fit, strength, and overall quality before delivery. SF Dental Lab follows strict quality checks to ensure consistency for outsourced cases.

Typical Turnaround Time

With a streamlined workflow and clear communication, most metal dental partials from SF Dental Lab are completed within 10 days. The exact timeline may vary depending on case complexity, material selection, and clinical requirements.

This structured production process allows SF Dental Lab to support clinics and dental labs outsourcing metal dental partials with reliable quality and predictable turnaround times.

Why Choose SF Dental Lab for Metal Dental Partials

Successful metal dental partial cases depend on precise fabrication and reliable lab support. Consistent fit, stable materials, and controlled production are essential to avoid delays and unnecessary adjustments.

SF Dental Lab supports clinics and dental labs outsourcing metal dental partials by providing well-managed workflows and clear case communication. Both Chrome Cobalt and Titanium options are available to meet different clinical and patient requirements.

With experienced technicians and strict quality checks at each stage, SF Dental Lab helps partners achieve predictable results. A stable 7–10 working day turnaround time allows clinics and labs to plan treatments with confidence while maintaining cost efficiency.

Conclusion

Metal dental partials remain a practical and dependable solution for partial tooth replacement when designed and produced correctly. Their comfort and performance rely not only on materials, but also on careful planning and accurate laboratory execution.

For clinics and dental labs that outsource metal dental partials, working with a structured and experienced lab partner can simplify case management and improve consistency. SF Dental Lab provides steady production support and dependable delivery for long-term cooperation.

If you are looking for a reliable outsourcing partner for metal dental partials, contact SF Dental Lab to discuss your cases and learn how we can support your daily workflow.

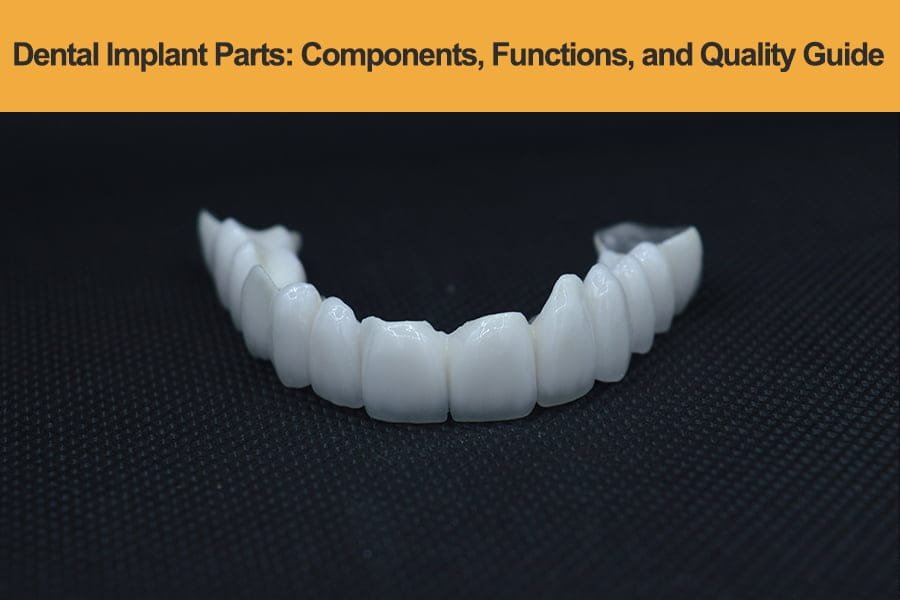

[…] dentures partials and metal partial dentures are both removable solutions, but they serve different clinical needs. Understanding their […]